Weatherstripping may not be as fun or sexy as the glimmering light from shiny wheels and chrome parts, but it will have a big impact on the end result of your project. Weatherstripping isn’t typically something you appreciate most of the time – unless it fails.

What is Weatherstripping?

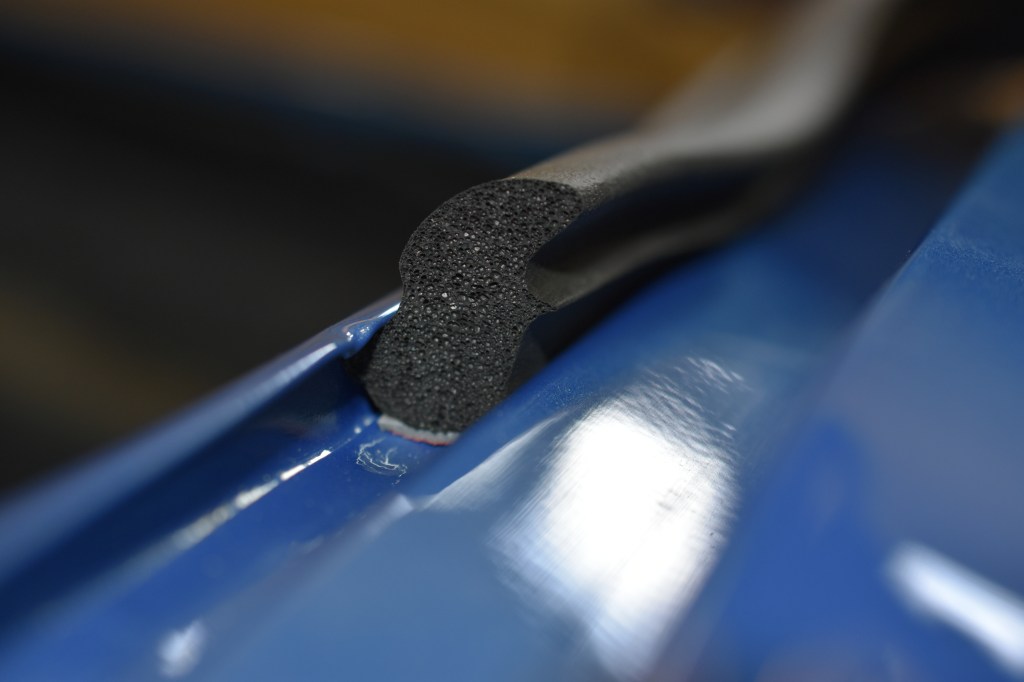

Weatherstripping is made of rubber, more specifically, ours is made of 100% EPDM rubber with no fillers. It goes around the doors, windows, trunk and other various openings of your car or truck to seal between the interior of your ride and all the things Mother Nature has to offer outside (water, dirt, wind, etc.).

For doors and trunks, a squishy sponge rubber is used because it has a little give in it to allow compression for a good seal.

For windows and windshields, a dense, hard rubber is used, sealing out rainwater and eliminating the wind noise.

Failing weatherstripping can cause a lot of problems:

- wind noise and rattling windows making for a noisy ride

- water leaks that cause rust, mold and a stained interior

- heat and air conditioning will not stay in

Proper Maintenance

Let’s say you’ve done your research, purchased new seals, and then installed them on your ride – how do you maintain them correctly? One of the most common questions we’re asked here at Steele is ‘What’s the best way to ensure your weatherstripping has a long life and is sealing the best that it can at all times?’

I’ve read a lot of chats and forums that tell you to use silicone spray, WD-40, armor all, grease and other like products. There are more companies than I can count that promote their products for maintaining and extending the life of your weatherstripping. But our experts here at Steele say this: All you need to do is keep the weatherstripping clean and dry and out of the sun when possible. That’s it.

This is not a matter of opinion, this is science. Like I mentioned earlier, our products are made of high-quality EPDM rubber that is far more ozone resistant than the parts that originally came on your classic car. But, one prevalent characteristic of EPDM rubber is that it has very poor resistance to solvents (petroleum distillates) and oils. Using the products that mentioned above can deteriorate the rubber and put you right back where you started, needing replacement seals.

Never apply rubber or vinyl treatments that have an oily or greasy nature, or any petroleum-based products onto your EPDM weatherstripping!

Different chemicals will impact rubber in different ways. Some will have a negative effect while others may be fine to use but won’t do anything to extend the life of the rubber. So, the best and safest option when you need to wipe down your weatherstripping is using soap and water.

At Steele, we’re more than just high-quality products, we’re your trusted resource for completing your weatherstripping projects with confidence.

Whether you’re working on a classic car or truck, street rod, RV, or boat, our expert team is here to help. If you have questions about weatherstripping or need product guidance, we’re just a call or click away.

📞 Call us at 800-650-4482

📧 Send us an email

💬 Chat with us live on our website

Need installation help?

Check out our How-To video series on YouTube for step-by-step guidance and tips.

Stay connected!

Follow us on Facebook and Instagram for updates, inspiration, and more.